Custom Metal Parts Drive Solutions

Moving Magtrol Forward with Innovative Manufacturing.

The Challenge:

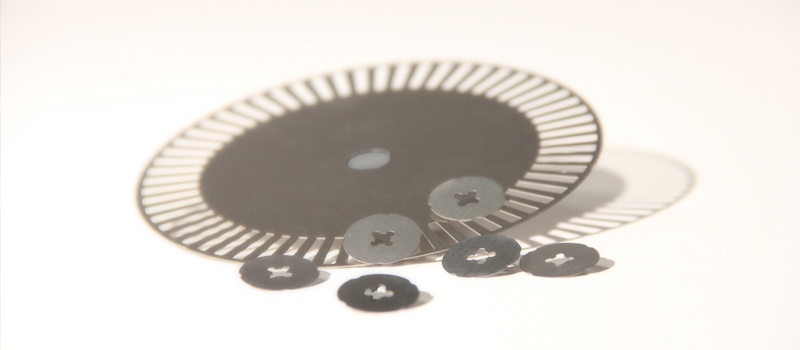

Magtrol is a leading manufacturer of motor test equipment and products to measure, control and monitor load-force-weight and displacement. Unhappy with their current metal parts vendor, the company set out to find a new partner with fresh ideas.

They contracted Switzer to solve issues with two different product groups. First, they needed a faster, more reliable manufacturing solution for high-precision timing disks with improved balance in their assembly. Second, while solving the first issue, our team discovered another opportunity for a more cost-effective process in the production of burr-free diaphragms.

The Response:

Our photochemical etching fit the bill for both applications. The ultra-accurate, repeatable process immediately corrected the quality issue of the timing disks. In the case of the diaphragms, we were able to shorten the manufacturing cycle by cutting multiple parts at once, as compared to the one-up punching method that was previously used.

“SWITZER HAS DONE SUCH A GOOD JOB ON THE COUPLE OF PARTS THAT THEY MADE FOR US THAT WE’RE CONTINUING TO SEND THEM NEW STUFF MONTHLY, EVEN DAILY.”

-

MECHANICAL ENGINEER AT MAGTROL